Differences between Single stage , double stage, three stage regenerative /Ring/Side Channel Blowers

Regenerative Blowers also named Ring Blowers or Side Channel Blowers - Rexblower

Classification of regenerative /Ring/Side Channel Blowers:

The regenerative /Ring/Side Channel Blowers can be divided into single impeller(single stage), doube impellers(double stage), and three impellers(three stage) . As the name suggests, it is defined by the number of built -in impeller. At the same power:

Pressure: Single stage <double stage<three stage

AirFlow: Single stage <double stage<three stage

Weight and volume: Single stage <double stage <three stage

Price: Single stage <double stage <three stage

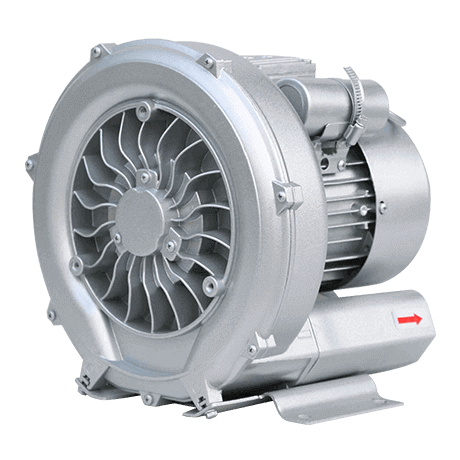

Single stage means that there is only one impeller, the outlet and the inlet of single stage blower are generally parallel, and the amount of air volume is smaller and can meet the work on food machinery, pharmaceutical machinery, material conveyor, printing machinery, industrial vacuum equipment, woodworking machinery, plastic machinery, textile machinery and other equipment;

SINGLE STAGE

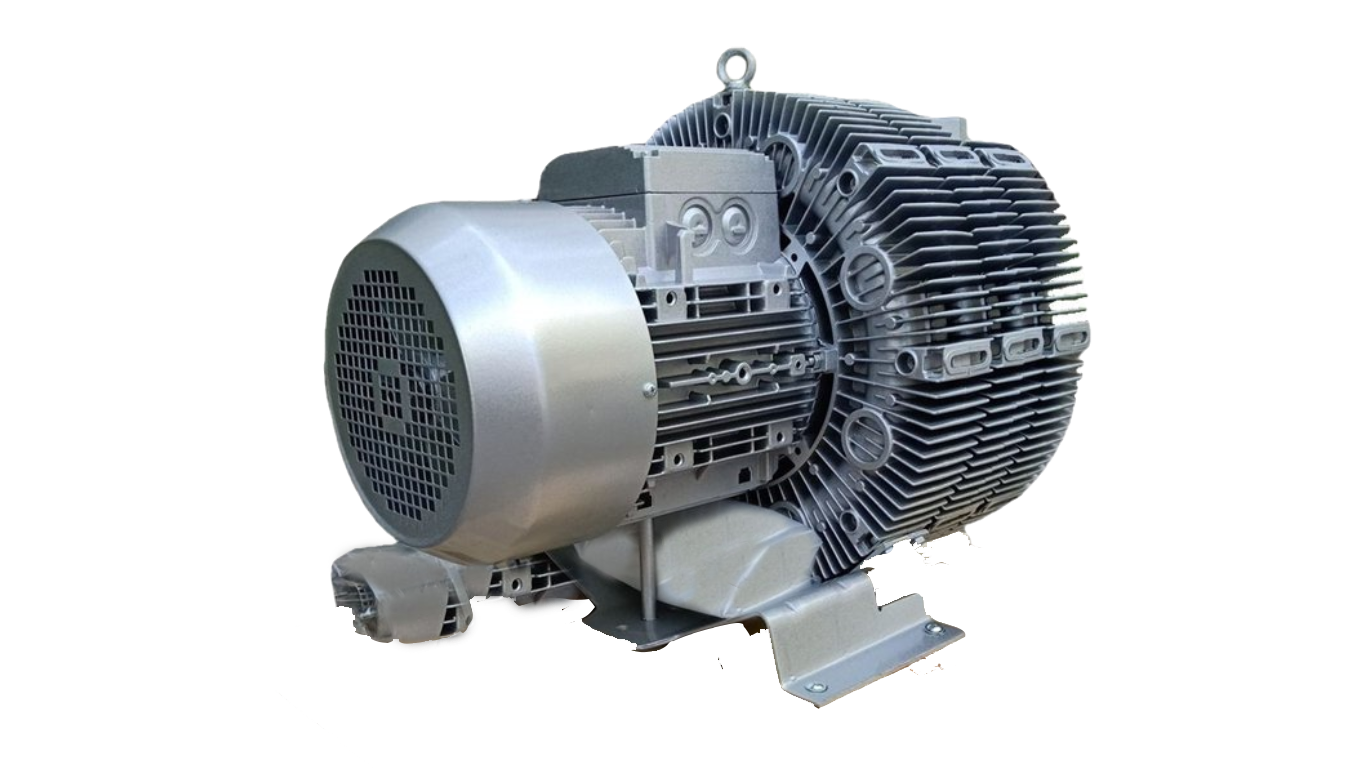

The double stage are designed with two impeller in the need for a single segment, the outlet and the inlet of double stage blower are generally not parallel. The airflow speed rotates faster and the air volume is also greater. The higher working performance requires that we have three stage of high -pressure blower, higher pressure ratio.

DOUBLE STAGE

THREE STAGE

IMPELLER

Rexblower support customized voltage and motor power service according to certain requirements.

Advantages of the Rexblower Regenerative /Ring/Side Channel Blowers

1. Blowing and Suction dual functions, one -machine with dual - functions, can be used for vacuum adsorption, gas transportation, can also be used as a closed circuit air circulation.

2. Running without oil, the output air is clean, because the fan relies on the input operation of power, and the internal components do not have any oil components, so do not need to worry about the problem of transporting air pollution and no impurities.

3. High pressure and high pressure. Compared with centrifugal fans and midstream fan, their pressure is much higher, which determines the pressure problem that other fan cannot meet. Essence

4. The pump part of blower is used to cast the overall die -casting of the hydraulic press, and the shockproof installation of the foot is installed. Then its requirements for the installation foundation are also very low, and it can even run normally without fixing the foot.