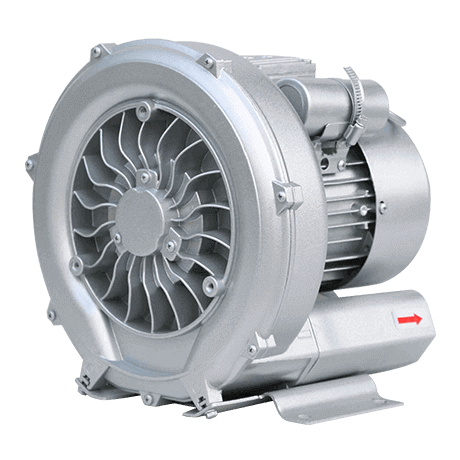

How to carry out the maintenance of the side channel blower (ring blower)

vortex air pump also named side channel blower, ring blower, vacuum pump

How to carry out the maintenance of the vortex air pump

The vortex air pump is an air circulation source for both blowing and air intake. It is suitable for paper cutters, ignition and oxygen reduction machines, coiling machines, filter tip forming machines, electroplating bath liquid stirring, atomizing dryer equipment, fish farming and oxygenation. , Wastewater treatment hydrolysis acidification tank, screen printing machine, photographic automatic pipe cutting machine, automatic feeding machine, water ointment filling machine, powder filling machine, arc laser welding machinery and equipment, film industry equipment, paper transportation , Cleaning of dry-cleaning clothes, gas ash removal, bottle drying, dust particle transportation, vegetable cleaning and drying, beverage bottle drying, circuit board dust removal, gas transmission, feeder, collection, etc.

How to maintain the vortex air pump?

1. The vortex air pump should be placed in a relatively stable area, and the surrounding environment should be clean, dry, and ventilated.

2. The rotation direction of the centrifugal impeller of the vortex air pump should be as consistent as possible with the direction of the arrow icon marked on the electric fan cover.

3. When the vortex air pump is working, the working pressure cannot exceed 9kpa, so as to prevent the air pump from being damaged due to excessive calorific value and the total flow of the motor over-current.

4. It is strictly forbidden for solids, liquids and corrosive gases to enter the pump body of the vortex air pump.

5. The filter screen and muffler equipment on both sides of the air inlet and outlet of the vortex air pump should be properly removed according to the situation to prevent blockage and damage to use.

How to maintain the vortex air pump?

1. The vortex air pump should be placed in a relatively stable area during the whole process of operation, and its surrounding environment should be cleaned, dried and ventilated.

2. The rotation direction of the centrifugal impeller of the vortex air pump should be as consistent as possible with the direction of the arrow icon marked on the electric fan cover.

3. Repair on time and add lubricating grease to the roller bearings on both sides like a general motor.

4. The filters and mufflers on both sides of the air inlet and outlet should be properly removed according to the situation to prevent blockage and damage to use.

5. The middle of the exhaust port and the outer pipe should be connected with a high-pressure hose for conductive soft connection.

The vortex air pump features a wide-pressure dual-frequency, maintenance-level IP55 motor and is certified according to the US 3C, which promotes it into a practical solution. It can be used in Europe, South America, Africa and Asia without any modification and re-inspection, and can be customized for production. REXBLOWER can produce different types and specifications of vortex air pumps according to customer requirements, and can also customize customized high-pressure fans with corrosion resistance, explosion-proof, anti-leakage, thermal maintenance, high temperature resistance, split type, DC power supply, etc.