Basic Info.

Color :CustomizedTrademark:Rexblower

Specification:CE

Origin:China

HS Code:8414599010

Transport Package:Packed in Wooden box

Rexblower OEM & ODM services are avaliable.

1.Supply ability

8,00 Set/Sets per Week2.Packaging & Delivery

Packaging Details:One set in one carton with wooden pallet or as per the clients' requrement.

Port:Shanghai or Ningbo Port

Lead Time:Ex stock

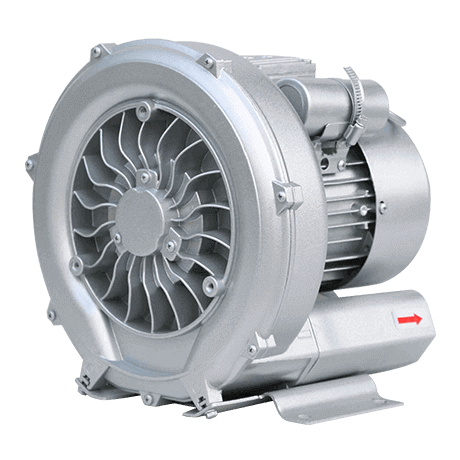

3.Three Leaf Roots Blower also named Tri-Lobe Roots Blower

Principle

Applications

The three-leaf Roots blower is mainly used in water treatment, pneumatic transportation, vacuum packaging, aquaculture, power plants, cement plants, electroplating, chemical industry and mining areas.4.Features

(1).Large air volume and pressure range.

Diameter: 32mm-400mm (1.25"-16")

Air volume: 0.38-283m 3 /min (13-9985CFM)

(2).The exhaust gas does not contain oil.

(3).Computer dynamic balance correction, low vibration and low noise.

(4).The air volume is stable, and the pressure change has little influence on the air volume.

(5).Special impeller design, high efficiency and energy saving.

(6).Simple and sturdy construction, trouble-free.

(7).Using first-grade grinding gears, high precision, long life and low noise.

(8).Strict quality management, standardized products.

(9).The impeller adopts the new planer six-axis processing method, which can be processed at one time, making it easy to replace, and it has higher precision.

5.Certification

Certification Name:CE, Issued By:LINKTEK6.Factory Information

Factory Size:1,000-3,000 square metersPlace of origin:China

No. of Production Lines :10s

Contract Manufacturing: OEM Service Offered ,Design Service Offered,Buyer Label Offereds

Annual Output Value:Above US$100 Millions

7.Payment Terms

T/T, Western Union, Paypal, Money GramTri-Lobe Roots Blower Main Parts

◆Host shell

The Roots blower casing, base, wall panel, fuel tank and rotor are all made of gray cast iron HT250, cast with resin sand and treated with aging. The surface is designed with ribbed protrusions, which not only makes it difficult to deform at high temperature, but also increases the surface heat dissipation area of the fan, so that the designed temperature rise of the fan casing can reach 160 °C. The interface is machined to make it smooth and flat to ensure airtight assembly.

◆Three-blade rotor

The Roots blower rotor is made of gray cast iron HT250, and the rotor blade profile is arc line. It is processed by a four-axis simultaneous CNC machining center made in Taiwan, and it is processed and formed at one time with extremely high precision. The rotor has undergone strict dynamic balance, and the precision reaches G2.5 level, so that the discharged air flow is quite smooth and continuous, and is fixed on the rotating shaft in the way of shrink fit. During operation, there is no contact and friction between the two rotors, and no water seal and lubrication are required. The static and dynamic balance of the rotating blades conforms to international standards.

◆Impeller main shaft

The material is heat-treated No. 45 high-quality carbon structural steel, imported quality through JIS hardness test. The material structure is average and the concentricity is extremely high to avoid eccentricity. Through the three-blade rotor, the shaft is sealed between the second oil tank shell, the bearing room and the main engine room, so that the lubricating oil cannot leak into the main engine room.

◆Transmission gear

1. In order to ensure freedom of vibration, silent operation and durability, the synchronous gear has the design feature of straight teeth. The material is SNCM21, nitride hardened and finely ground, has a run rate of 1.7, and meets AGMA quality standards. The transmission gear is grade 5 precision, or the precision is JIS grade 1 standard. Strict quality standards not only extend gear life, but also achieve low noise.

2. The gear is fixed to the shaft by a conical tight fit.

◆Bearing

1. Bearings are designed to guarantee a life of at least 100,000 hours (according to ABMA standards) under conditions of speed, pressure and temperature at the same time.

2. In order to facilitate the maintenance and replacement of bearings in the future, the bearing chamber is equipped with a labyrinth shaft seal to prevent foreign matter from entering, and the bearing chamber shell is made of cast iron HT250.

3. The bearing adopts Japanese NSK bearing.

◆Seal

1. The Roots blower is equipped with a sealing system to ensure the free flow of oil and avoid lubricating oil pollution.

2. The seal adopts labyrinth seal, metal dynamic and static ring, oil throwing ring and ventilation balance hole. In order to ensure the leakage of the air in the fan cavity, at the same time, the lubricating oil in the oil tanks on both sides cannot enter the fan cavity, so as to ensure the cleanliness of the air outlet.

3. The drive shaft seal adopts 2 double-lip rubber oil seals.

For special gases, other sealing methods can be used, such as: carbon rings and mechanical seals

◆Lubrication

1. Both ends of the bearing and the synchronizing gear are lubricated with splash oil instead of grease. The lubrication effect is more thorough. Increase mechanical life.

2. Splash oil lubrication can be optimized with a lubricating oil ring.

3. The fuel tank shell has reinforcing ribs, which allow a higher level of heat transfer and avoid excessive oil temperature.

4. The lubricating oil system has a large enough capacity and cooling device to provide proper oil to the gears and bearings, and the oil change interval for continuous operation is not less than 2,000 hours.

5. Provide an observation window to observe the oil level. Each viewing window is marked with the safe oil level when the fan is running and can accurately display the oil level when the fan is off.

◆Base

For the convenience of user installation, we have made a special mounting base for the Roots blower and motor. The base is welded by channel steel and steel plate, and is machined to ensure that the Roots blower and the motor drive shaft are parallel to each other. The blower provides elastic shock pads to reduce the vibration of the Roots blower, and provides the foundation screws required for each set of equipment installation.

◆Cooling

The Roots blower is naturally cooled by lubricating oil. The fuel tank is made of aluminum alloy casting, and the lubricating oil is high-end synthetic gear oil. Compared with the use effect of ordinary mineral gear oil, the service life of bearings and gears is significantly improved, and the service life of synthetic oil is 3 times that of mineral oil, which reduces the use cost.