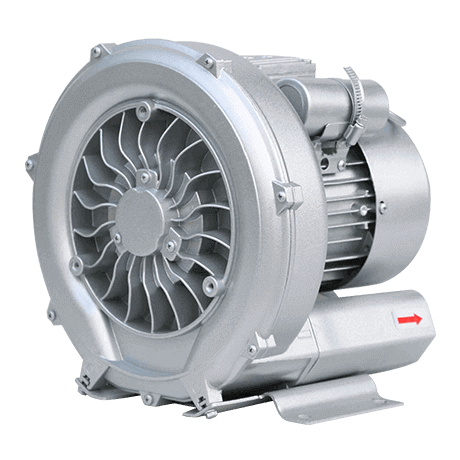

Drying matching special vortex blower / ultrasonic blow drying special fan

Drying matching special vortex blower is mainly used for: paper cutting machine, combustion air-lowering machine, cigarette filter molding machine, electroplating tank liquid stirring, atomizing dryer, water treatment blow-up, fish gas, screen printing press, photographic system Edition machine, injection molding machine automatic loading dryer, liquid filling machine, powder filling machine, welding equipment, film machinery, paper transport, dry cleaning, air dust removal, dry bottles, gas transmission, feeding, collection and so on.

Drying matching special vortex blower configuration:

1. Shell material: vortex gas pump using ultra-strength die-cast aluminum, die-cast aluminum and Mercedes-Benz car wheel Yi the same aluminum, relative to ordinary aluminum alloy, die-cast aluminum is more robust, relative to the iron shell fan, more lightweight role.

2. Motor performance: vortex gas pump using Taiwan Yuxin motor, Yuxin motor is a broadband, wide-voltage motor, included in: single-phase 110V/230V industry three-phase: 220/380/415/660V, motor frequency can be 45-75HZ F-class insulation class, the advantages of domestic motors can not reach the process, favored by domestic and foreign customers.

3. Wind oil seal: vortex gas pump using German MERKEL seal, German MERKEL material using fluoroelas rubber can withstand -25 degrees C to 300 degrees C. Compared with the general oil seal work, the temperature of the lip edge is higher than the operating medium temperature of 20 to 50 degrees C, the performance is more stable, maintenance-free, longer life.

4. Fan bearings: vortex gas pump core components using germany SKF, Japan NSK brand bearings, bearing zui high can withstand 350 degrees Celsius, 4000 rets per minute speed. For domestic Lo axis, human-based bearings, stable performance, low noise, maintenance-free, longer life, can ensure that the fan runs longer.

Drying matching special vortex blower products mainly have the following characteristics:

(1) By using AC motor as the driving force, the project will be installed directly on the motor roel, to achieve completely contactless compression, to ensure that the vortex gas pump in zero maintenance to maintain up to 20,000 hours of continuous and efficient operation.

(2) The use of dual-frequency wide voltage technology, so that the protection level to IP55 (insulation level F or H), to meet the needs of different regions of the world current frequency, voltage, with frequent start-up performance, overload capacity, automatic protection start-up fast, safe and reliable advantages.

(3) The use of bearing pre-structure, the pump bearings installed outside the compression cavity, to achieve a large dynamic balance configuration, to achieve any installation of the product, to maintain long-term continuous balanced operation;

(4) The whole machine is oil-free, the transmission system does not need lubrication. To make the product application field more extensive, the air quality requirements of medical equipment, printing industry precision printing, electronics industry integrated circuit manufacturing process can be used. At the same time, no additional auxiliary equipment is required for efficient work, and operating costs are reduced.

(5) The design of imperms and wind channels has been accurately calculated and demonstrated, the blade length, wind path arc, curvature has been optimized, compared with similar products, in the same power input performance increased by more than 30%, and the product wind noise is lower, the whole machine operation is less than 70 dedes.

(6) Compared with other kinds of real air pumps, it has: smooth operation, low noise, energy saving, positive and negative pressure, flow, efficiency and other indicators to meet the standards of Siemens gas ring fan in Germany, the whole machine is compact, light weight, small size, high operating pressure difference, blow-suction two-use.

Precautions for the use of drying matching special vortex blowers:

(1) The load phenomenon (RB series) occurs when it is fully closed.

(2) The load phenomenon (CX, TB, HTB, CS, PF, MS series) occurs at full opening, at this time using a current meter to confirm the size of the current flow, buffer adjustment, usually used in the fixed current.

(3) Switch in one minute back and forth on and off, will cause the motor overheating, should be added to avoid.

(4) Inverter control - when using the drive power waveform distortion, motor sound is large, vibration is also large. If you are operating with an inverter and the temperature rises or vibrates, stop running. Generally, please use under the following conditions.

(5) Larger weekly wave value (swing number) - shall be within the number of weekly wave set on the mark and within the fixed current.

(6) Smaller weekly wave number (swing number) -- above 30 Hz and within the fixed current.

(7) The single-phase motor cannot be operated as a drive.