Four methods to seal a high pressure blower/fan

Four methods to seal a high pressure blower/fan

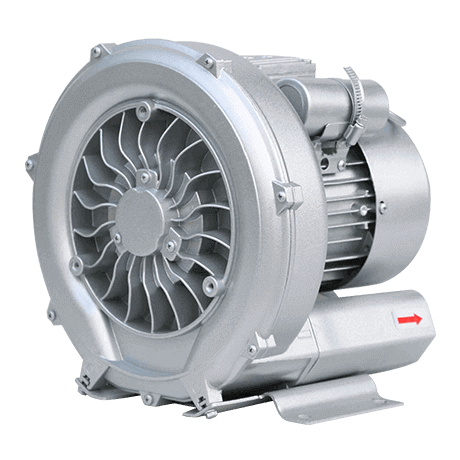

The performance of high-pressure blower seal is one of the important indicators of operation. This is especially true when transporting toxic, harmful, flammable, explosive or valuable gases. If the seal is not good, not only leakage of a large number of valuable gases, more serious is will cause serious environmental pollution. Take a look at the four ways high-pressure fans are sealed

1. Labyrinth seal

Labyrinth seal is also called LaBeouling seal, comb seal, in the fan products are the most widely used, in the fan products of the interstitial seal is basically the use of maze seal, the shaft end of the air transmission seal, in the case of low pressure are also used maze seal.

2. Floating ring seal

Floating ring seal is the use of the spindle and floating ring between the formation of pressure oil film, oil film pressure and external load (the pressure of the work quality) to achieve the balance, to seal the axial leakage of the working medium. Because the floating ring seal has the advantage of automatic positive center, so the seal gap can be smaller, the leakage volume is reduced, the pressure of the seal body can be adjusted with the pressure of the sealed medium, the floating ring and shaft between the liquid moth state, thus avoiding mechanical wear. This seal is used when pressure is high or when corrosive gases are transported, the conveying gas does not leak outwards.

3. Mechanical seal

Mechanical face seal is a kind of sealing device which achieves the axial rotation of the seal by the pre-tightening of the static and dynamic ring end face moths and the pressure of the medium pressure and the pressure of the elastic element. Mechanical seals generally use pressure higher than the sealed medium 2.5 to 3.5 sealing fluid (permeable oil) to seal the sealed medium.

During rotation, the friction surface establishes an oil film, and the pressure of the oil film is from the outside, from large to small, to achieve balance with the sealed medium. Since the seal pressure is always greater than the sealed medium, the sealed medium generally does not leak, and the sealing fluid has a small amount of leakage in the in, the leaking seal will be recycled through the return oil hole. Due to structural changes, the amount of oil in the mechanical seal is greatly reduced compared to the amount of oil used in the floating ring seal, but it belongs to the oil film seal.

4. Dry air seal

Dry air seal is a gas film seal, is the current flat compressor in, sealing effect of a sealing form. It is a sealing medium with nitrogen or other harmless gases. The cleanliness of sealing gas is high and there is a more complex gas supply system.